A Homeowner’s Guide to Modified Bitumen Roof Systems in Texas

When you think of a flat or low-slope roof, you might picture old-school tar and gravel. Modified bitumen is the modern, high-tech evolution of that classic concept, engineered to be tougher, more flexible, and far more reliable.

It’s essentially asphalt (bitumen) that has been supercharged with advanced polymers, like rubber or plastic. This blend creates a rugged, waterproof membrane that’s perfect for the flat and low-slope roofs you see all over Texas commercial buildings and even some homes.

What Are Modified Bitumen Roof Systems

Think of it this way: you have your standard asphalt, the same stuff used in roads for ages. By itself, it can get brittle in the cold and soft in the heat. But when you blend it with specialized polymers, you get something entirely new—a material that can stretch, resist impacts, and maintain its integrity through brutal DFW summers and wet East Texas winters.

This "modification" is the key. It transforms basic asphalt into a robust, multi-layered roofing system that provides a seamless, waterproof barrier. It’s designed to overcome the classic weak points of older flat roofing materials, offering a shield that moves and flexes with the building instead of cracking under pressure.

The Foundation of Modern Flat Roofing

Modified bitumen really took off in the U.S. back in the 1970s as a major upgrade to traditional built-up roofing (BUR), which involved messy, on-site layers of hot tar and felt. Instead, modified bitumen offered a cleaner, more consistent solution: factory-manufactured rolls. It was like switching from building a brick wall by hand to installing a precision-engineered, prefabricated panel.

So, why has it remained a go-to choice for decades? A few key reasons:

- Superior Durability: The polymer reinforcement makes the membrane incredibly resistant to punctures and tears. This is huge for roofs that have HVAC units or regular foot traffic.

- Excellent Waterproofing: The large sheets are installed with overlapping, sealed seams (often heat-welded), creating a single, monolithic surface that water simply can't penetrate.

- Proven Performance: This isn't a new, untested technology. It has a long, successful track record of protecting buildings in the toughest climates.

- Versatile Installation: Contractors can choose from several installation methods, allowing them to pick the safest and most effective technique for a specific project.

The roofing industry continues to rely on this tried-and-true system. The global market for modified bitumen is projected to hit USD 15.74 billion by 2033, driven by its reputation for resilience and cost-effective maintenance. It just works.

To give you a clearer picture, here’s a quick rundown of what makes modified bitumen a top contender for Texas properties.

Modified Bitumen Roofing at a Glance

| Feature | Description | Primary Benefit for Texans |

|---|---|---|

| Composition | Asphalt (bitumen) mixed with rubber (SBS) or plastic (APP) polymers. | Withstands extreme temperature swings from summer heat to winter freezes without cracking. |

| Structure | Multi-layered system with a base sheet, bitumen membrane, and protective top surface. | Provides redundant layers of protection against leaks, especially during heavy rain. |

| Durability | Highly resistant to punctures, tears, and foot traffic. | Ideal for commercial roofs with HVAC units or other equipment that requires servicing. |

| Seam Integrity | Seams are typically heat-welded, cold-adhered, or self-adhered for a watertight bond. | Creates a monolithic, seamless barrier that stands up to wind-driven rain and ponding water. |

| UV Protection | Top surface is often embedded with granules or coated to reflect solar radiation. | "Cool roof" options help reduce energy costs by reflecting the intense Texas sun. |

This combination of toughness and waterproofing is what makes it such a reliable choice.

Later, we'll get into the two main "flavors" of this material—SBS and APP—each bringing something different to the table. Understanding this foundation is the first step to seeing why it’s more than just a "tar roof." It’s a sophisticated system built for longevity. You can learn more about how it stacks up against other roofing system types in our detailed comparison.

Choosing Your Armor: SBS vs. APP Explained

When you get into the nitty-gritty of modified bitumen roofing, you'll find it really comes in two main "flavors": SBS and APP. These aren't just minor differences—they're two completely different chemical formulas designed to protect your building in very specific ways. The right choice for your property boils down to a single, critical question: what’s the biggest threat your roof is going to face year after year?

In North and East Texas, that answer often involves punishing hailstorms and wild temperature swings. For other properties, the relentless Texas sun is the primary enemy. SBS and APP offer specialized protection for each of these scenarios. Think of it like choosing between flexible, impact-absorbing armor and a hard, heat-deflecting shield.

SBS: The Flexible Defender

SBS (Styrene-Butadiene-Styrene) is easiest to think of as rubber-infused asphalt. Manufacturers blend bitumen with a synthetic rubber polymer, creating a membrane with incredible flexibility and elasticity. It’s a lot like a high-quality rubber band; you can stretch it, and it snaps right back to its original shape without breaking.

This "memory" and flexibility is the secret to its success. When a big hailstone smacks an SBS roof, the membrane has enough give to absorb the shock and rebound, drastically cutting down the risk of a puncture or fracture. This same quality helps it survive Texas's notorious temperature shifts—like going from a freezing winter morning to a balmy afternoon. An SBS membrane expands and contracts right along with the building, preventing the kind of stress cracks that lead to leaks.

This makes SBS the hands-down winner for the Dallas-Fort Worth Metroplex and other parts of Texas that get hammered by hail. Its ability to handle thermal shock and direct impacts gives it superior resilience where it truly counts. In fact, the global market for SBS is valued at around USD 11.8 billion, largely due to this impressive flexibility and resistance to aging. Introduced back in the 1970s, it solved the age-old problem of asphalt's brittleness, offering elongation up to 300% and handling temperatures from -20°F to 200°F. You can explore the research behind these market trends to learn more.

APP: The Rigid Shield

On the other side, you have APP (Atactic Polypropylene), which acts more like a hard plastic shell. This version is made by mixing asphalt with a plastic polymer, creating a much tougher and more rigid surface. While it doesn't have the bounce-back flexibility of SBS, it shines in a different, equally important area: UV resistance.

Think of an APP roof as having its own built-in sunscreen. The plasticized membrane forms a hard, almost candy-like shell that’s exceptionally good at deflecting solar radiation and withstanding constant high heat. Its high melt point also makes it perfect for torch-down installations, as it flows like liquid under the flame to create a seamless, monolithic layer.

For buildings in areas with intense, sustained sun but a lower risk of severe hail, APP is a fantastic choice for a durable shield against the sun's degrading power.

SBS vs. APP Modified Bitumen Comparison

Making the right call between SBS and APP is crucial for getting a roof that will last in our demanding Texas climate. This table breaks down the key differences to help you decide.

| Characteristic | SBS (Styrene-Butadiene-Styrene) | APP (Atactic Polypropylene) | Best Choice for Texas Climate |

|---|---|---|---|

| Primary Trait | Elasticity & Flexibility (Rubber-like) | Rigidity & UV Resistance (Plastic-like) | Depends on the specific local threat. |

| Performance | Excellent impact and hail resistance. Handles thermal shock and expansion/contraction extremely well. | Superior resistance to UV degradation and high heat. High melt point is ideal for torching. | SBS for hail-prone areas like DFW. APP for areas with extreme sun but less hail. |

| Installation | Can be installed via torch, cold-applied adhesive, or self-adhered methods. | Best suited for torch-down application due to its high melt point and smooth flow. | Varies by contractor preference and building specs, but both are common. |

| Weakness | Can be more susceptible to long-term UV damage without a proper protective coating. | Less flexible, making it more prone to cracking from building movement or direct impact. | SBS needs good surfacing. APP is vulnerable to impact. |

Ultimately, your location within Texas is the biggest factor. For most properties in the DFW metroplex and East Texas "hail alley," the superior flexibility and impact resistance of SBS make it the clear winner.

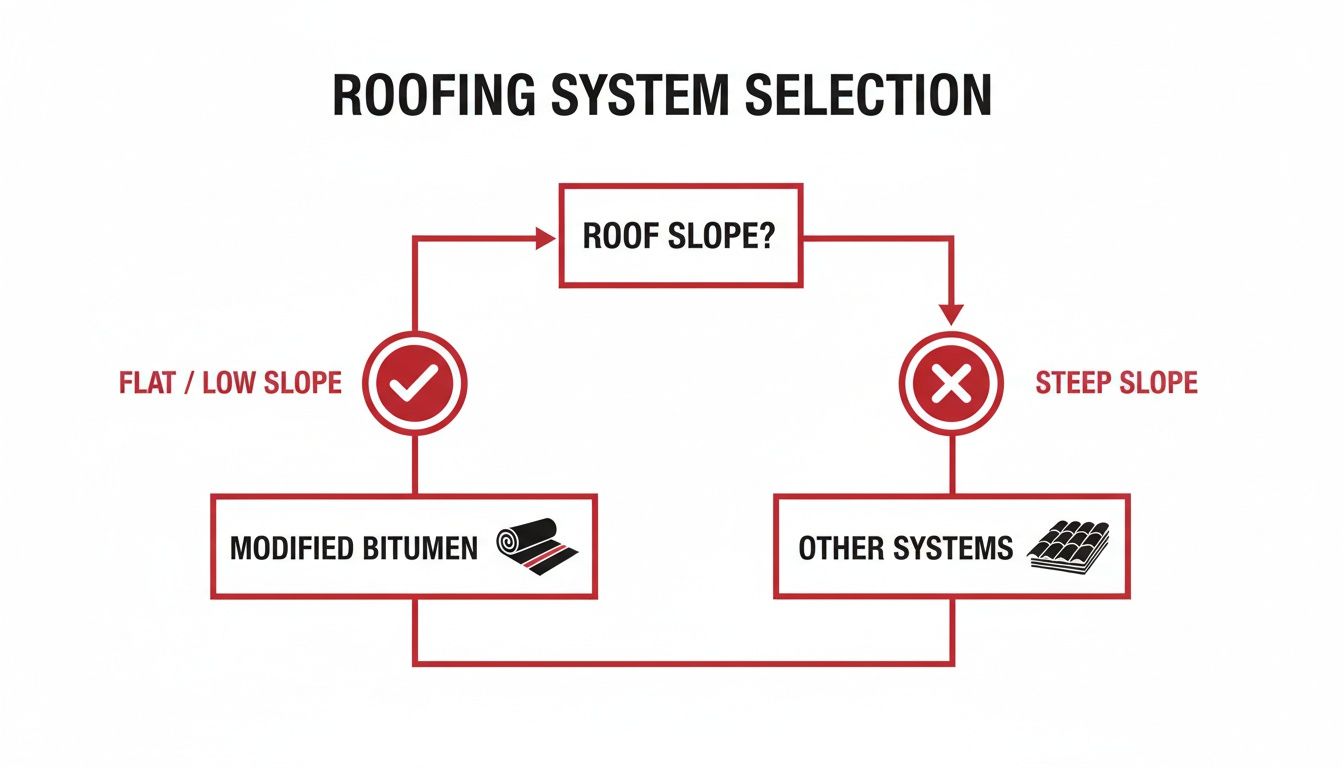

Deciding which type of modified bitumen to use is a crucial first step, as this simple decision tree shows.

As the flowchart confirms, once you've determined a low-slope system is needed, the next fork in the road is choosing between the flexible protection of SBS and the rigid shield of APP.

The Installation Process From Start to Finish

Even the best roofing material in the world is only as good as the crew that installs it. Putting down a modified bitumen roof is a true craft, a blend of precision and power. The method your contractor chooses will come down to your building's structure, safety factors, and the specific membrane they're using.

Knowing how these systems go down helps you understand what's happening overhead and why a pro might recommend one technique over another. There are three main ways to install these tough membranes, and each has its own place.

The Torch-Down Method

The classic, time-tested technique is the torch-down installation. This is the one that probably comes to mind when you picture a flat roof being installed. It involves a high-intensity propane torch to heat the underside of the bitumen roll as the crew lays it out. This intense heat melts the asphalt, basically welding it to the base sheet or substrate underneath.

As the roll moves forward, the molten bitumen creates an incredibly strong, watertight bond. It’s a lot like soldering pipes—the heat fuses separate pieces into one solid, monolithic layer. This process is famous for creating some of the strongest and most reliable seams in the business.

But working with an open flame demands a high level of skill and rigorous safety measures. It’s really best for buildings with concrete or steel decks where fire risk is low. For a new commercial build or an empty warehouse in the DFW area, torch-down is often the top choice for its brute strength and lasting performance.

The Cold-Applied Method

So, what about when an open flame is a non-starter? On a building with a wood deck, or around sensitive sites like an occupied school or hospital, contractors pivot to the cold-applied method. This approach trades the torch for powerful roofing adhesives.

The process is a lot like using a heavy-duty glue. The crew spreads the adhesive across the roof surface with a squeegee, and then the modified bitumen membrane is rolled right into it. A heavy roller is used to press the membrane down firmly, ensuring a tight bond and pushing out any trapped air.

This method completely removes the fire risk of torching and the powerful fumes from hot-mopped asphalt, making it a much safer option for occupied properties or sensitive environments. The bond is fantastic, but the roofer's technique has to be perfect to avoid any weak spots.

The Self-Adhered Method

The newest player in the game is self-adhered installation. These are high-tech modified bitumen rolls that come from the factory with a powerful adhesive already on the back, covered by a simple release film. The installation is surprisingly simple in concept, but it demands careful, detailed work.

You can think of it like applying a giant, industrial-grade sticker. The crew lays out the roll, peels back the protective film, and carefully sets the sheet down. They’ll usually apply a special primer to the roof deck first to get the best possible stick. The whole thing is then pressed down with a weighted roller to lock in the bond.

This modern method brings a lot to the table:

- Speed: It’s typically the fastest way to get a roof on, which can save on labor costs.

- Safety: With no flames and no hazardous fumes, it’s the safest installation you can get.

- Cleanliness: The entire process is neat and tidy with very little mess.

Thanks to its safety and speed, self-adhered roofing is quickly gaining ground in both commercial and residential flat roofing. The adhesive technology has come a long way, and when it’s installed right, it delivers performance that can stand toe-to-toe with the old-school methods.

Weighing the Pros and Cons for Your Property

Every roofing material comes with its own set of trade-offs, and modified bitumen roof systems are no different. It's a fantastic blend of toughness and waterproofing, but it’s smart to look at the whole picture before making a decision. Getting a balanced view means you're investing in a roof that actually fits your building's needs, your budget, and what you expect from it long-term.

When you look at both sides honestly, you can weigh its proven durability against the specific installation skills and costs involved. This way, there are no surprises down the road.

Advantages of a Modified Bitumen System

Let's start with its biggest selling point: incredible toughness. The polymer reinforcement creates a membrane that can really take a beating. This makes it perfect for roofs that see a lot of foot traffic from HVAC crews or other maintenance teams. That high resistance to tears and punctures is a massive leg up on some of the softer, single-ply options out there.

Another huge win is the multi-layered waterproofing. Most modified bitumen systems use at least two layers—a base sheet and a cap sheet—that are fused together. This creates built-in redundancy. If something were to ever compromise the top layer, the one underneath acts as a backup, which gives you incredible peace of mind during those intense downpours we get in East Texas.

Here are a few more compelling perks:

- Proven Track Record: Modified bitumen isn't some new, unproven technology. It's been protecting buildings for over 50 years, giving it a long history of reliable performance.

- Weather Resistance: Whether you go with the flexible SBS to handle hail impacts or the more rigid APP to fight off the sun's UV rays, the system is built to handle extreme temperature swings without cracking.

- Straightforward Repairs: On the off chance a leak or puncture does happen, a professional can usually find and patch it without a huge hassle. Repairs are typically done with heat welding or cold adhesives, making maintenance fairly simple.

The combination of puncture resistance and a multi-ply design creates a seriously robust barrier that's tough to get through. This resilience is exactly why modified bitumen is still a top choice for commercial buildings and low-slope residential roofs.

Disadvantages to Consider

The most critical factor on the flip side is the need for skilled labor. Installing modified bitumen, especially the torch-down method, is a true craft that requires experience and absolute attention to safety. An inexperienced crew can easily create bad seams that will leak or, even worse, create a serious fire hazard.

The system's weight is another thing to think about. As a multi-ply, asphalt-based product, it's just plain heavier than single-ply membranes like TPO or EPDM. For some buildings, you might need a structural engineer to verify that the roof deck can handle the extra load. This detail is an important consideration when you're looking at the differences between a flat roof vs a pitched roof.

Finally, you have the environmental side of things. As an asphalt product made from petroleum, it’s not the greenest option from a manufacturing perspective. However, things are getting better. Many modern systems now include recycled materials, and "cool roof" granular surfaces can reflect a ton of solar heat, which boosts energy efficiency and helps offset its initial environmental footprint over the life of the roof.

Costs, Lifespan, and Maintenance in Texas

When you’re looking at a new roof, it always boils down to a few key questions: what’s the price tag, how long will it last, and what does it take to maintain it? For modified bitumen roof systems, the answers are pretty solid, offering a great mix of long-term value and manageable upkeep. This is where you see how your investment really performs in the real world.

A well-installed and cared-for modified bitumen roof is a serious long-term asset. Even in a tough climate like ours here in Texas, you can realistically expect it to last 20 to 30 years. That kind of lifespan makes it a dependable choice for property owners who value durability and don’t want the headache of frequent replacements.

Of course, a roof’s longevity isn’t just a given—it’s something you have to earn with a little proactive care. Think of it like changing the oil in your car; a little routine maintenance goes a long way in preventing huge, expensive problems down the road.

Budgeting for Your Modified Bitumen Roof

The cost for a new modified bitumen roof across Dallas-Fort Worth and East Texas isn't a one-size-fits-all number. Every project has its own unique quirks that influence the final price. For a deeper dive into the numbers, check out our guide on how much a new roof costs.

Here are the main factors that will shape your quote:

- Roof Accessibility: Is your roof tough to get to? Steep pitches or multiple levels mean more labor and safety gear, which bumps up the cost.

- Material Selection: The type of membrane you choose—SBS or APP—will affect the price, as will the specific thickness and quality of the product.

- Installation Method: Torch-down, cold-applied, and self-adhered systems each come with different labor and material costs.

- Existing Roof Condition: If we have to do a full tear-off of the old roof, that adds significant labor and disposal fees to the job.

A Simple Maintenance Checklist

Good maintenance is what gets you that full 20- to 30-year lifespan and helps keep your building dry. But if a leak does spring on your flat roof, you need to act fast. You may need to call in professional water damage restoration services to handle the aftermath.

To get the most out of your investment, stick to this simple maintenance plan:

- Do Routine Inspections: Get up there at least twice a year—think spring and fall—and after any big storm. Look for any blisters, cracks, or punctures in the membrane.

- Clear Debris and Drains: Get rid of leaves, branches, and anything else that could clog your drains, scuppers, or gutters. Preventing "ponding water" is the most critical maintenance task for any flat roof, period.

- Check Seams and Flashing: Look closely at where the roof meets walls, vents, and HVAC units. These spots are the usual suspects for leaks, so you need to make sure those seals are tight and intact.

Proactive upkeep isn’t just about fixing what’s broken—it’s about stopping problems before they start. A simple inspection and cleaning routine can easily add years to your roof's life and save you thousands in premature replacement costs.

The numbers back this up. These systems offer proven longevity and are cost-effective over time. The global market for roofing-specific modified bitumen is projected to grow from USD 952 million in 2025 to USD 1,180 million by 2031. Key data shows these membranes resist UV damage 2-3 times better than standard asphalt, and the more flexible SBS versions command over 50% of the market share. You can read more about these market insights and projections. This growth is a direct reflection of the material's trusted performance in the field.

How to Hire the Right Roofing Contractor

You can pick the absolute best roofing material on the market, but if it's installed incorrectly, you've just wasted your money. That’s the hard truth. Finding the right contractor is every bit as important as choosing the right system.

A flawless modified bitumen roof installation is the difference between a roof that serves you well for 25 years and one that becomes a decade-long headache of leaks and repairs. This isn't just general roofing, either. The work, especially torch-down application, demands a serious level of skill, experience, and an obsession with safety that, frankly, not every roofer has.

Vetting contractors isn't just a step in the process; it is the process. You're looking for a partner who gets the unique challenges these materials face in our intense Texas climate. A true pro doesn't just put the roof on—they stand behind their work for years, giving you peace of mind every time a storm rolls through.

Essential Vetting Questions for Your Contractor

To sort the real experts from the crowd, you have to ask the right questions. Think of this checklist as your secret weapon when you start calling for quotes. You’re not just looking for someone who can do the job; you’re looking for someone who has mastered it.

Get these questions answered right out of the gate:

- Local Experience: "How many modified bitumen roofs have you actually installed right here in DFW or East Texas? Can you give me a few addresses of local projects I can drive by and look at?"

- Manufacturer Certifications: "Are you certified by any of the big names like GAF, CertainTeed, or Siplast? Can I see a copy of your certification?"

- Installation Method: "For my specific building, which installation method do you recommend, and why? If it's torch-down, what are your exact safety protocols?"

- Texas Licensing and Insurance: "Can you send over a copy of your Texas roofing license along with your general liability and worker's comp insurance certificates?"

This first round of questions will quickly tell you who’s serious. A seasoned professional will expect these questions and have all the documentation ready to go.

Verifying Credentials and Understanding Warranties

Once you’ve narrowed it down to a few good candidates, it's time to dig into the paperwork. This is where you confirm they are who they say they are and understand what kind of protection you’re getting long-term. Never, ever just take a contractor’s word for it. Always verify.

A contractor's skill in handling insurance claims and manufacturer warranties tells you a lot about their professionalism. In a place like Texas, where storm damage is a constant threat, this isn't a bonus—it's a necessity.

Before you even think about signing a contract, get crystal-clear answers on these points.

- Check Their Insurance: Don't just look at the certificate. Call the insurance agency listed and confirm the policy is active and provides enough coverage for a project of your size.

- Break Down the Warranty: You need to understand two different warranties: the manufacturer's warranty on the material and the roofer's own workmanship warranty. Ask about the duration, what’s covered (and what isn't), and how you file a claim if something goes wrong.

- Map Out the Storm Damage Process: Talk through how they manage insurance claims after a storm. An experienced local roofer will have a dialed-in process for documenting damage, meeting with insurance adjusters, and making sure your claim is handled fairly and efficiently.

Hiring a contractor is a massive decision. By following this guide, you can be confident that you’re putting your property in the hands of a qualified, trustworthy expert who will install a durable modified bitumen roof the right way.

Got Questions About Modified Bitumen? We've Got Answers.

We get it. Choosing a new roof for your commercial property is a big decision, and you probably have a few lingering questions. It's smart to do your homework. Below, we've tackled some of the most common questions we hear from property owners right here in Texas.

Let's clear things up so you can feel confident about your next steps.

How Long Does a Modified Bitumen Roof Really Last?

You can realistically expect a well-installed and maintained modified bitumen roof to last 20 to 30 years. The key variables are the quality of the initial installation and consistent upkeep. In our Texas climate, things like keeping drains clear of debris and having the seams checked periodically make all the difference in hitting that 30-year mark.

Is Modified Bitumen a Good Choice for Hail?

It’s an excellent choice, especially the SBS (Styrene-Butadiene-Styrene) type. Think of SBS as asphalt with a dose of rubber mixed in. That rubber-like quality gives the material incredible flexibility and impact resistance, allowing it to literally bounce back from hail strikes that would crack or puncture more rigid roofs. For a place like Dallas-Fort Worth, it’s one of the toughest options out there.

Can You Walk on a Modified Bitumen Roof?

Absolutely. This is one of its biggest selling points. Modified bitumen is tough and highly resistant to punctures, so it can easily handle the foot traffic from HVAC crews and other maintenance teams. While it's built to take a beating, you might notice some surface scuffing over time in high-traffic zones. For buildings with constant rooftop activity, designated walkway pads are a simple solution.

The Bottom Line: Thanks to its multi-ply, reinforced build, modified bitumen is one of the most durable and walkable flat roof systems you can get. It's practically made for commercial buildings that have equipment on the roof.

Is This an Environmentally Friendly Roofing Option?

That’s a fair question, and the answer has a few layers. Being a petroleum-based product, its manufacturing process isn't inherently "green." But the industry has made some real progress.

The biggest win for the environment comes from choosing a "cool roof" version. These have a reflective, light-colored granular surface that bounces a huge amount of the sun's heat away from your building. This helps you:

- Slash your building's cooling costs and use less energy.

- Reduce the urban heat island effect, a big deal in our metro areas.

- Prolong the roof's lifespan by minimizing damage from thermal shock.

While the material itself has an impact, making it highly energy-efficient over its 20-30 year life is a smart, sustainable move for any Texas property owner.

Ready to see if a durable modified bitumen roof is the right solution for your Texas property? The experts at Hail King Professionals offer free, same-day inspections to provide you with a clear, honest assessment. Schedule your no-obligation consultation today!